Manure Technologies

Technologies commonly used alone or together to treat and manage manure.

Use the following links for NEAT Tool Solution details, most solutions fall into one of these categories:

Glossary

Manure Collection

Flush System

Manure is collected by flushing the pen or lane with water to a pit or holding tank.

Flume System

Manure is scraped to a flume (a small channel of flowing water) that is flushed to a pit or holding tank.

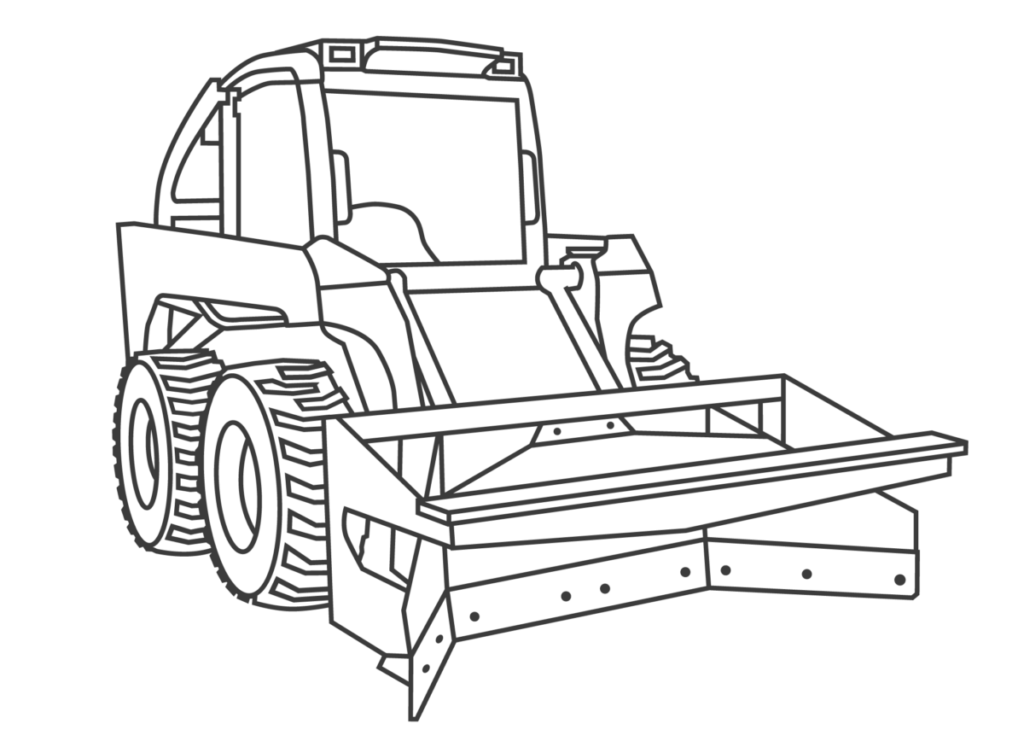

Scrape System

Manure is scraped to a pit or holding tank.

Vacuum System

Manure is vacuumed and delivered to a pit or holding tank.

Sand Removal

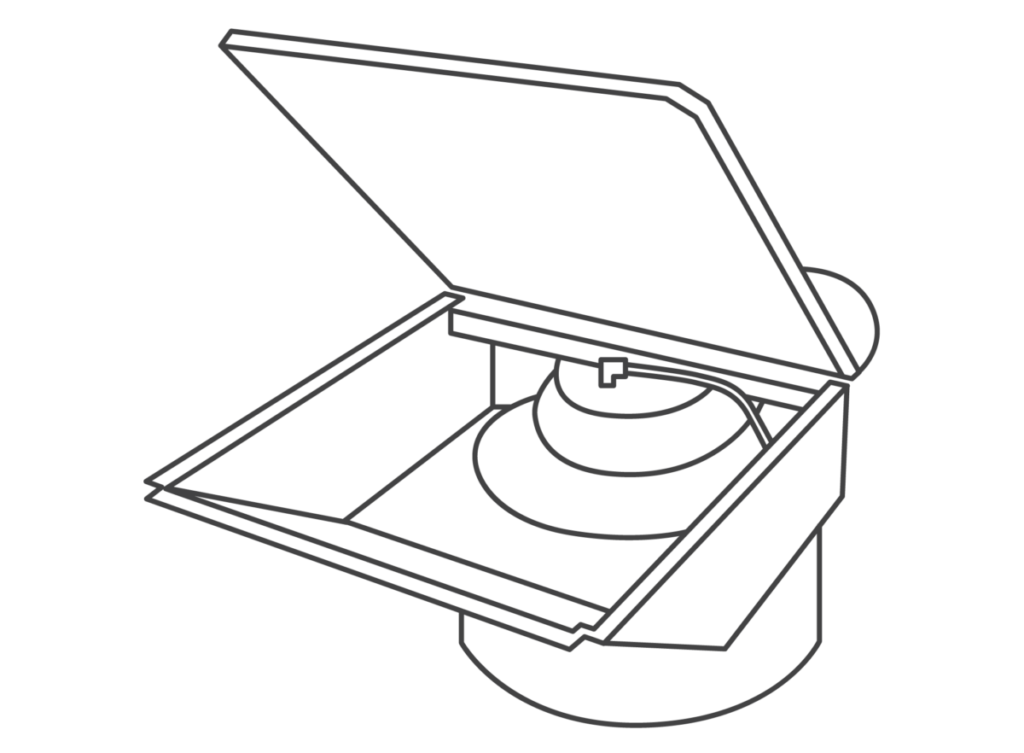

Sand Manure Separator

Mechanical systems for removing sand from manure.

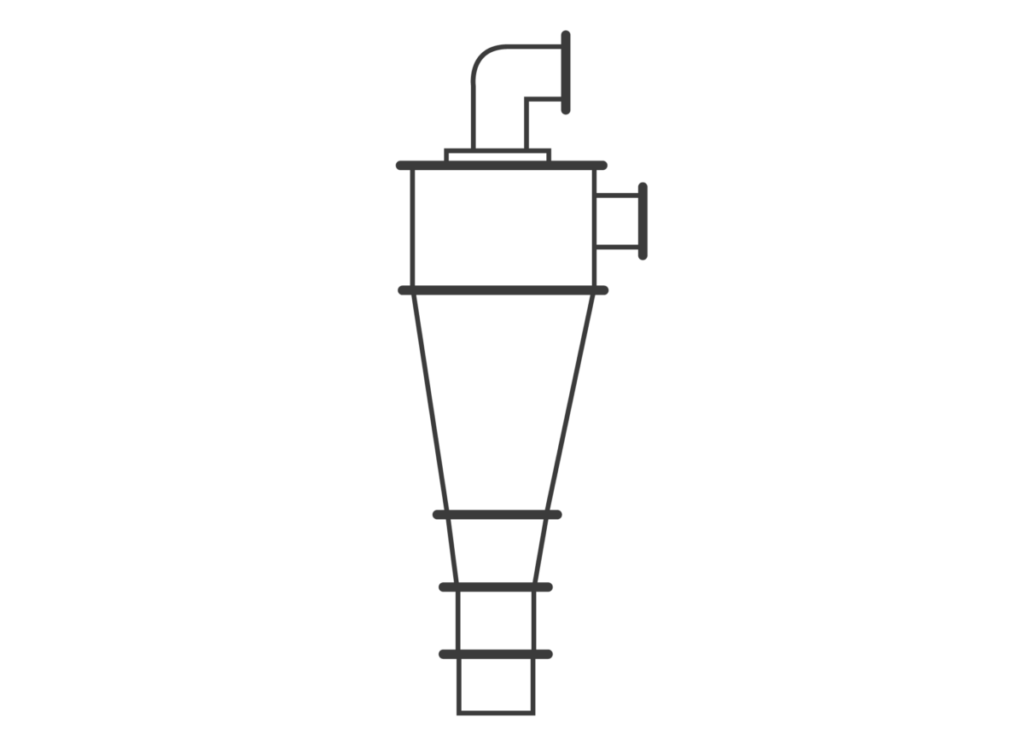

Hydro-Cyclone

Static funnel shaped separators that remove sand and heavy particles from a liquid waste stream by means of centrifugal force imparted by the flow of the water through the body of the device and preferential flow to two controlled outlets.

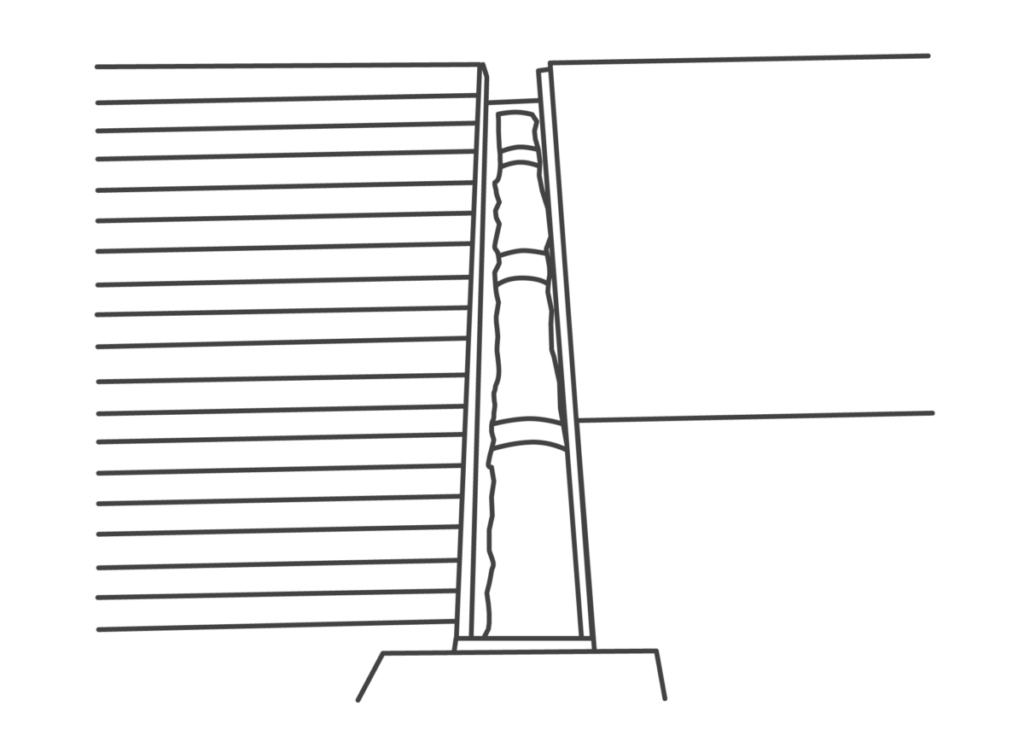

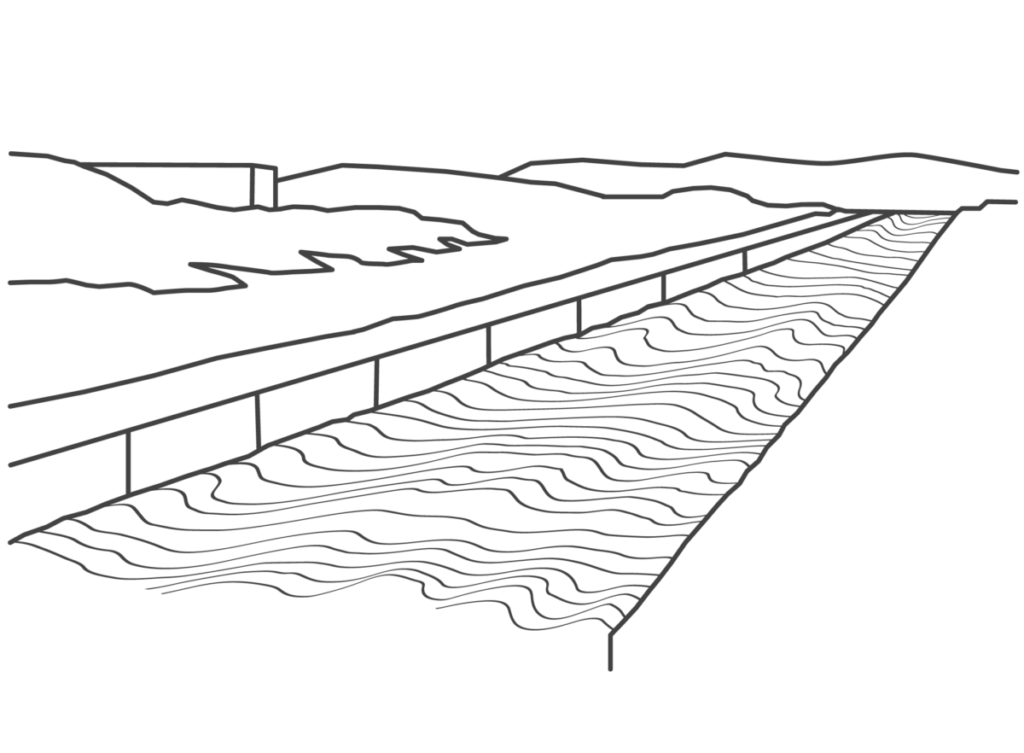

Sand Settling Lane

Long lanes designed to remove sand by slowing the flow of a dilute manure stream and allowing the sand to settle by gravity separation.

Coarse Solids Separation

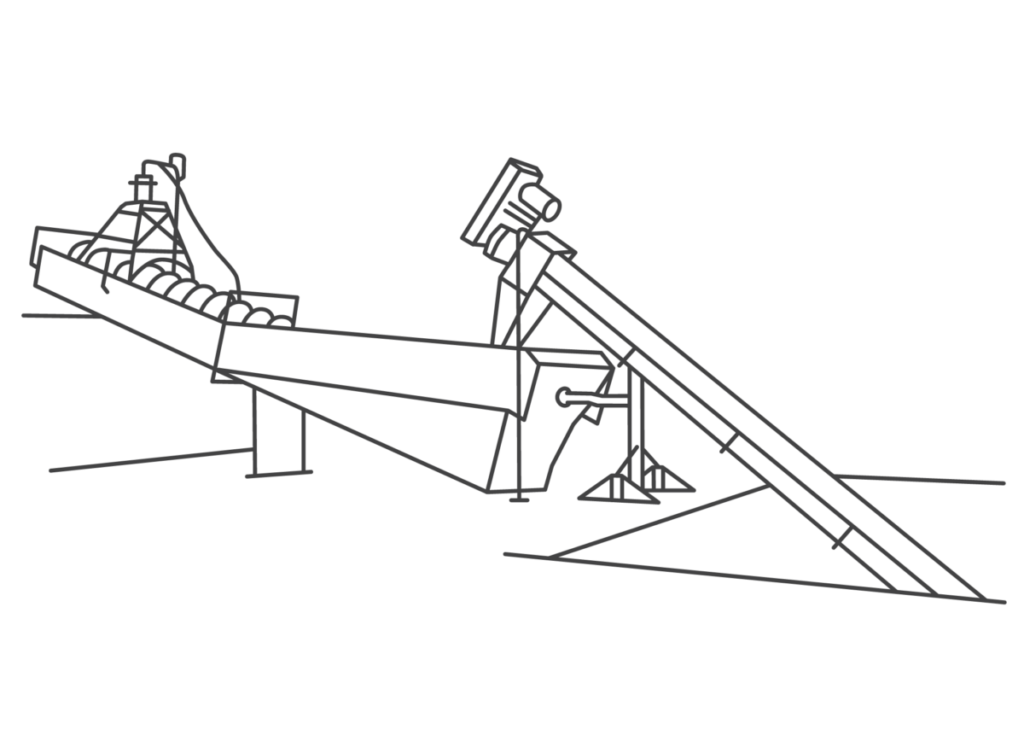

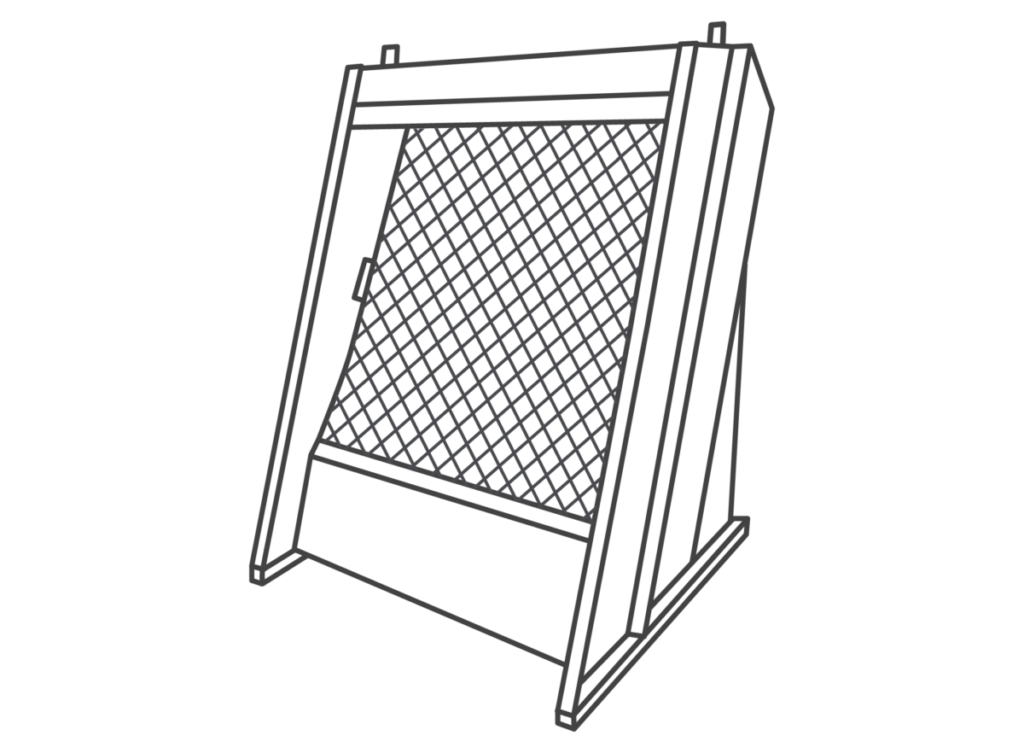

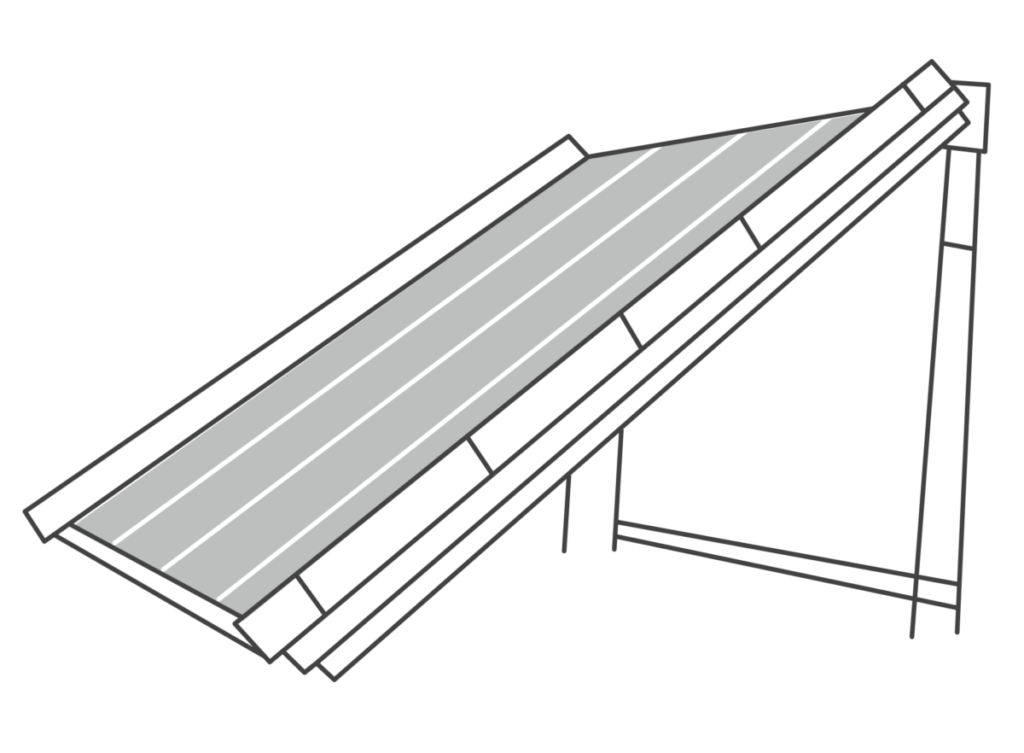

Slope Screen

Sloped wedge-wire screens that diluted manure is pumped over to remove the coarse solids, often followed by screw presses or rollers to remove additional water.

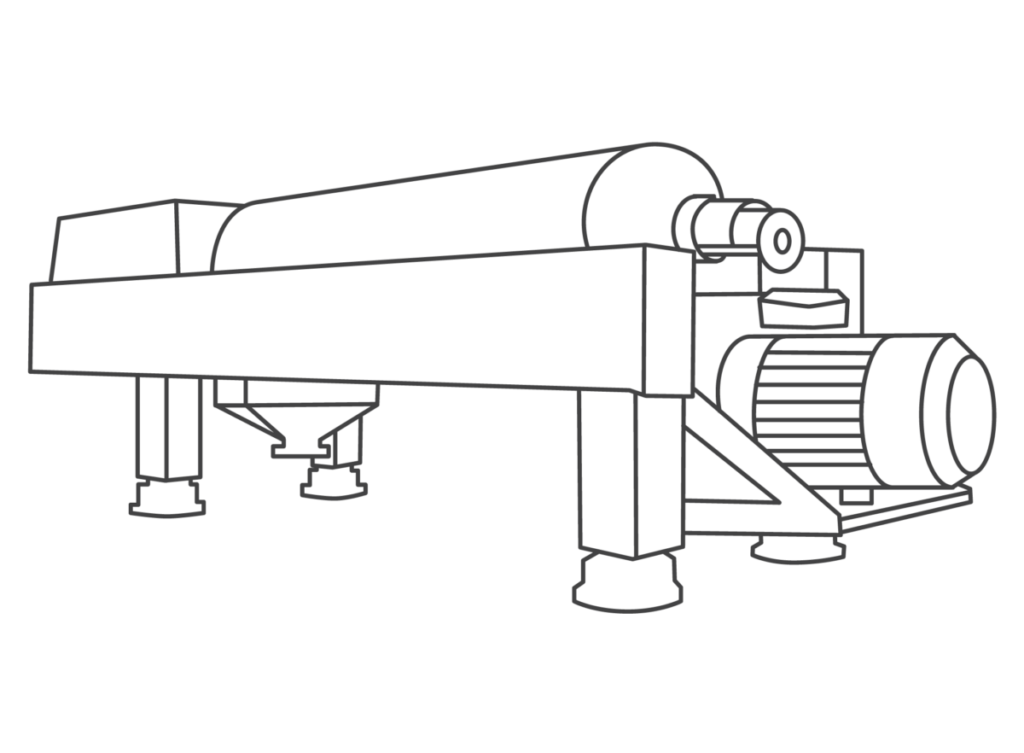

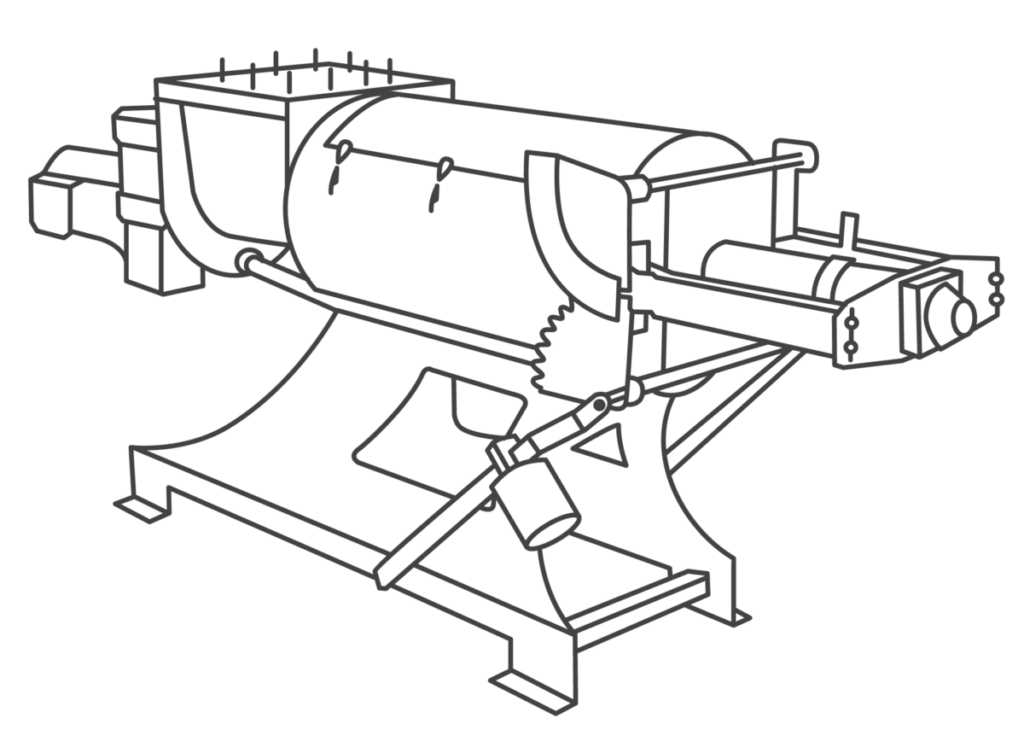

Screw Press

A wedge-wire screen cylinder that manure is forced through by an auger to force out the water, back pressure is maintained on the material in the cylinder by means of a gate or gates at the discharge of the cylinder.

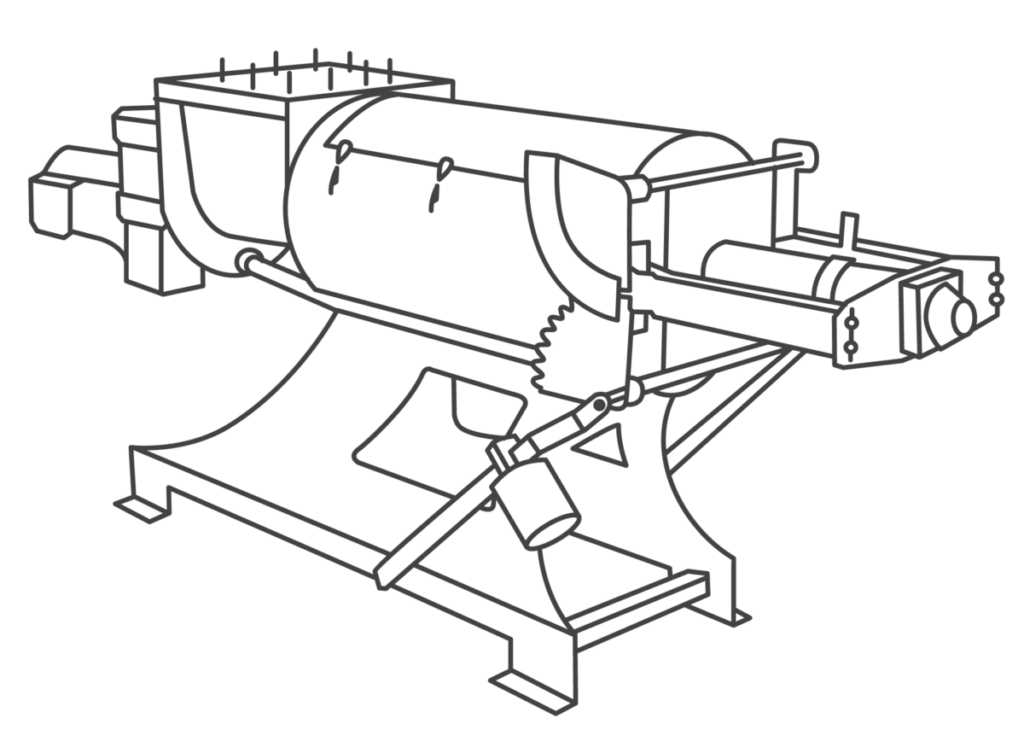

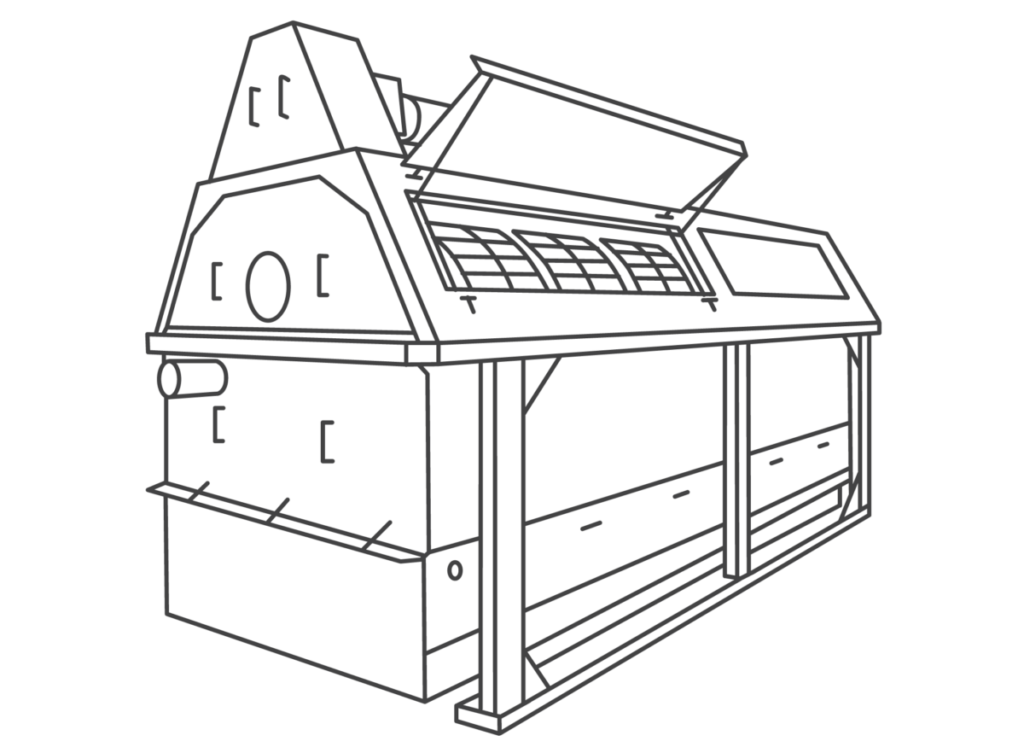

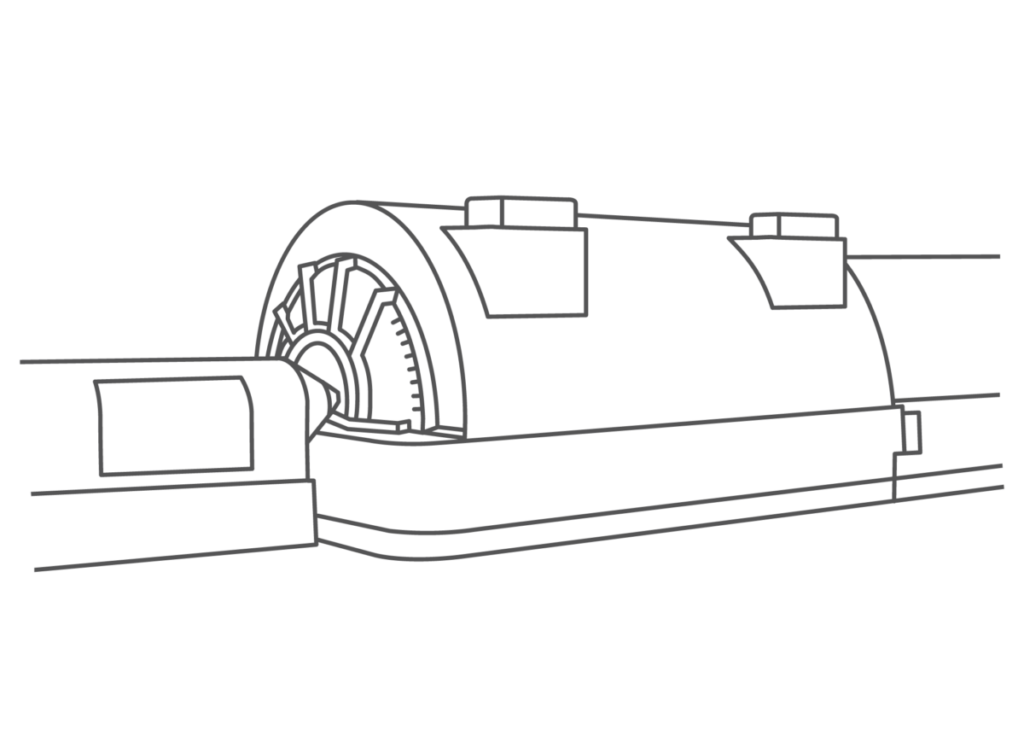

Rotary Drum Screen

Rotating drums of wedge wire or screen that manure is pumped through to remove the liquid, often followed by screw presses or rollers to remove additional water.

Fine Solids Separation

Polymer or Coagulant Flocculation

Introduction of select chemicals to induce small suspended particles to bind together into larger particles or flocs so that they can either float or sink, leading to separation and removal.

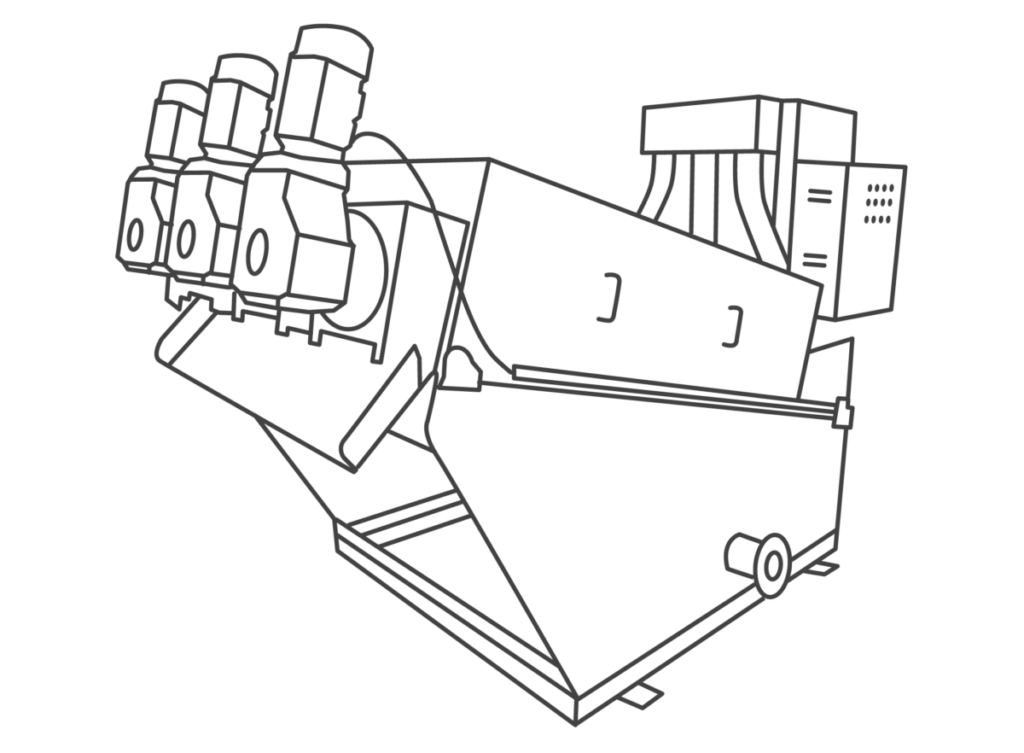

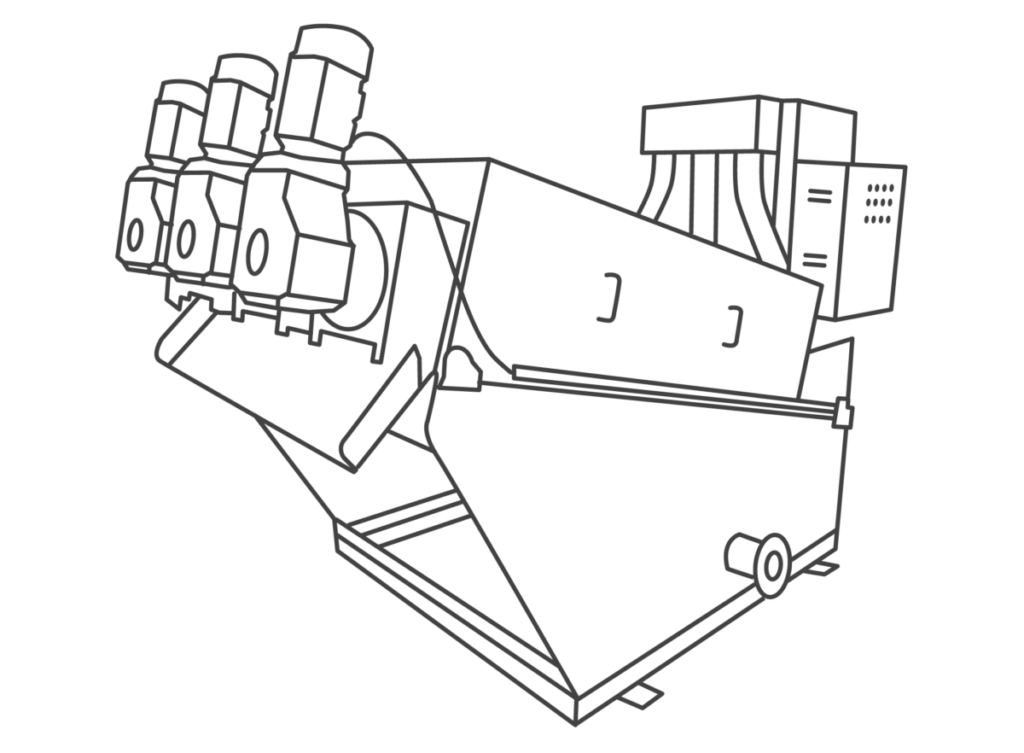

Moving Disc Press

A cylinder made up of many vertically arranged plates that manure is forced through by an auger to force out the water, back-pressure is maintained on the material in the cylinder by means of a gate or gates at the discharge of the cylinder, may or may not be assisted by polymers or coagulants also used for dewatering following other fine solids separation systems.

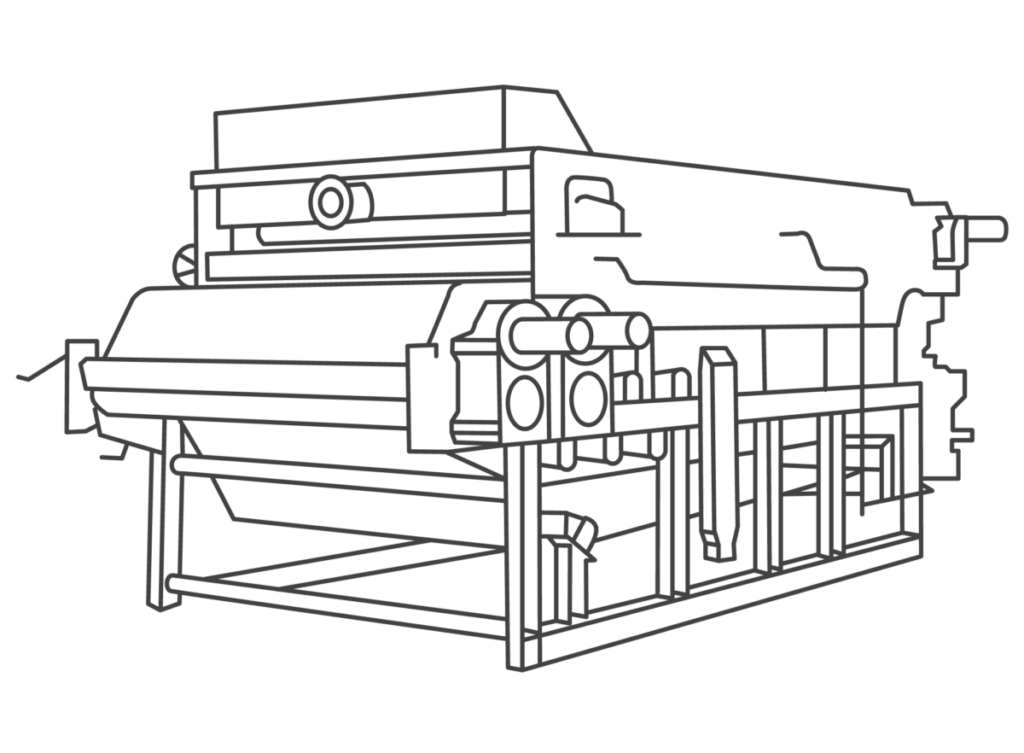

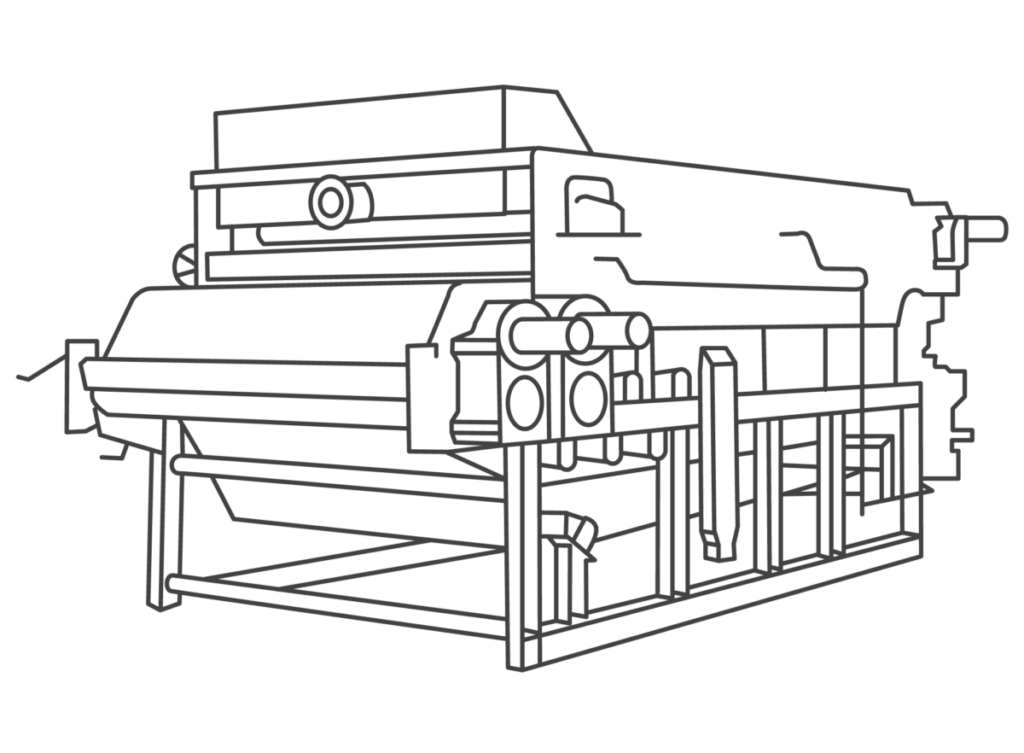

Belt Filter Press

A long screen in the form of a belt with rollers that allows for separation of fine solids usually used with polymers or coagulants also used for dewatering following other fine solids separation systems.

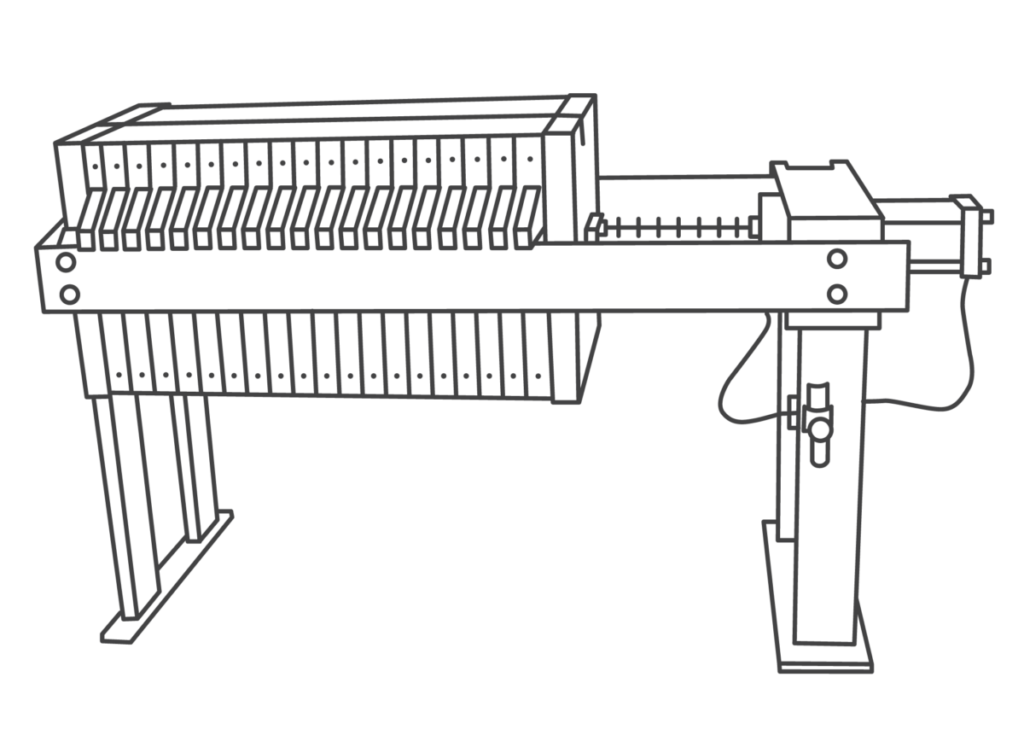

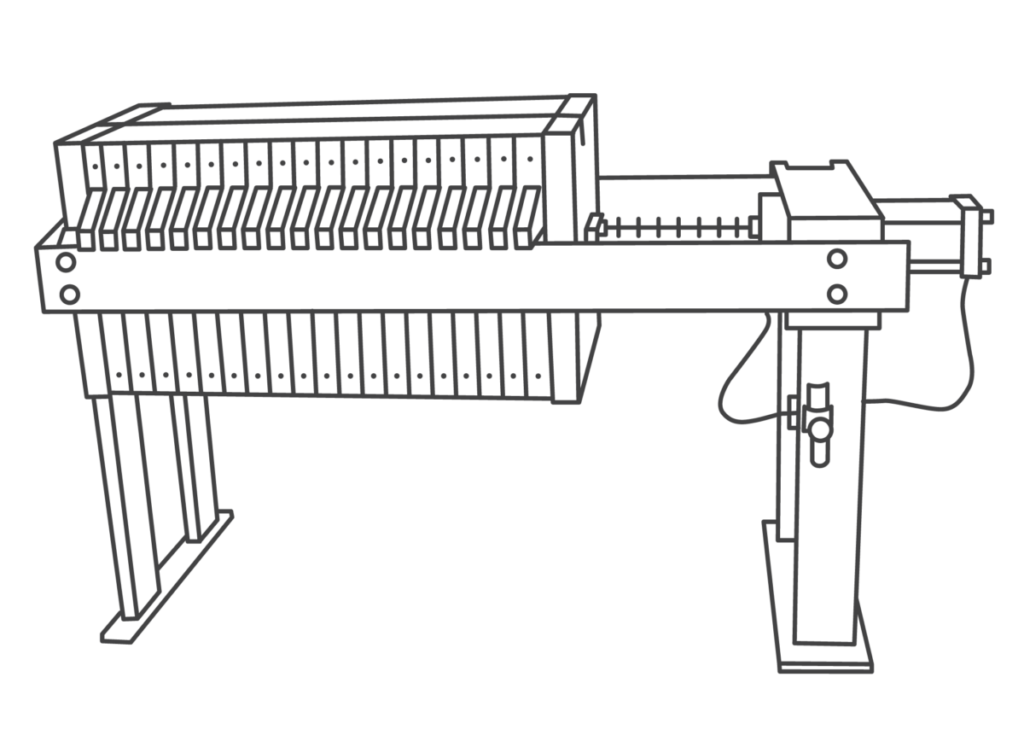

Plate Presses

Fine screens attached to a series of plates that are pressurized by the inflow of dilute waste usually used with polymers or coagulants. also used for dewatering following other fine solids separation systems.

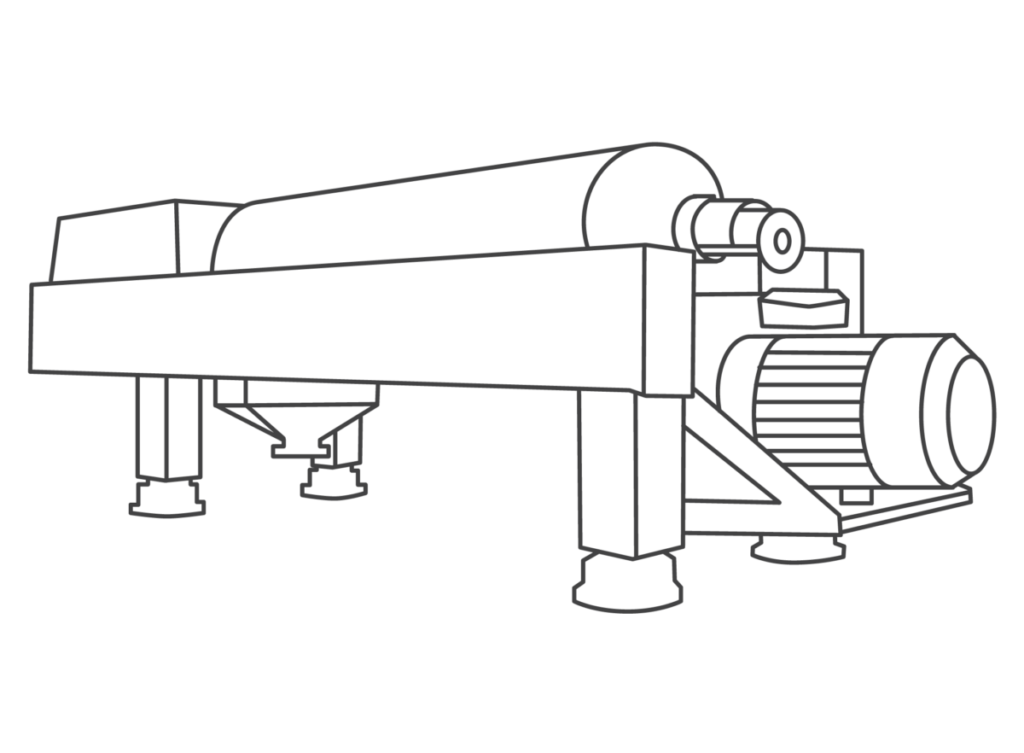

Centrifuge

Physical separation of fine particles by centrifugal force may or may not be assisted by polymers or coagulants, also used for dewatering following other fine solids separation systems.

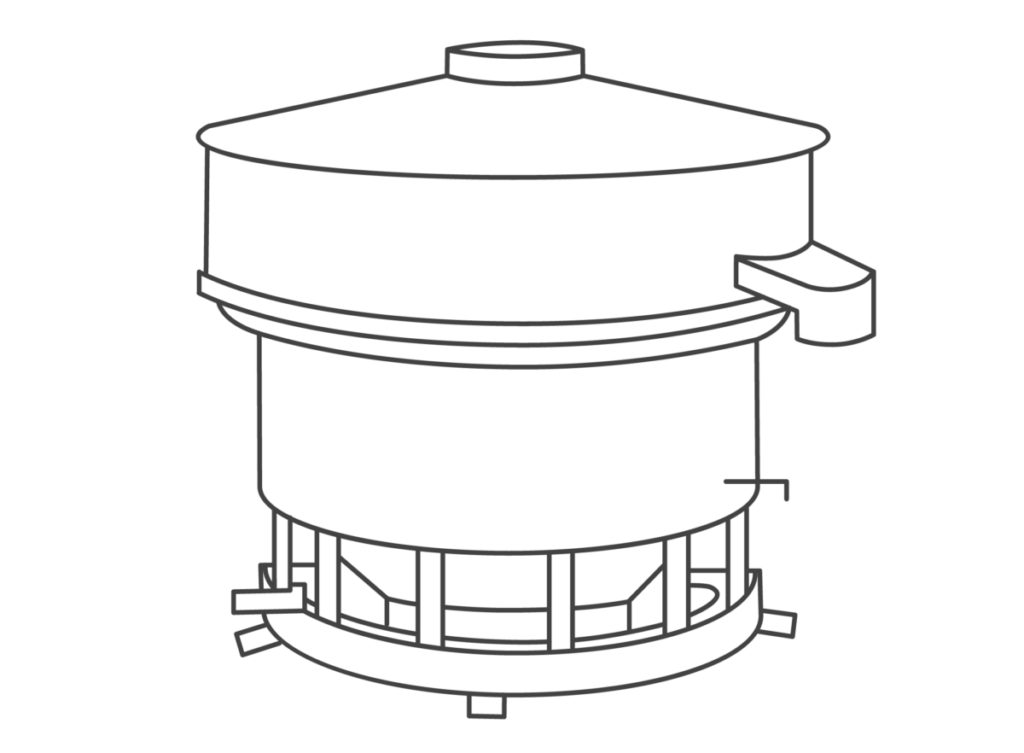

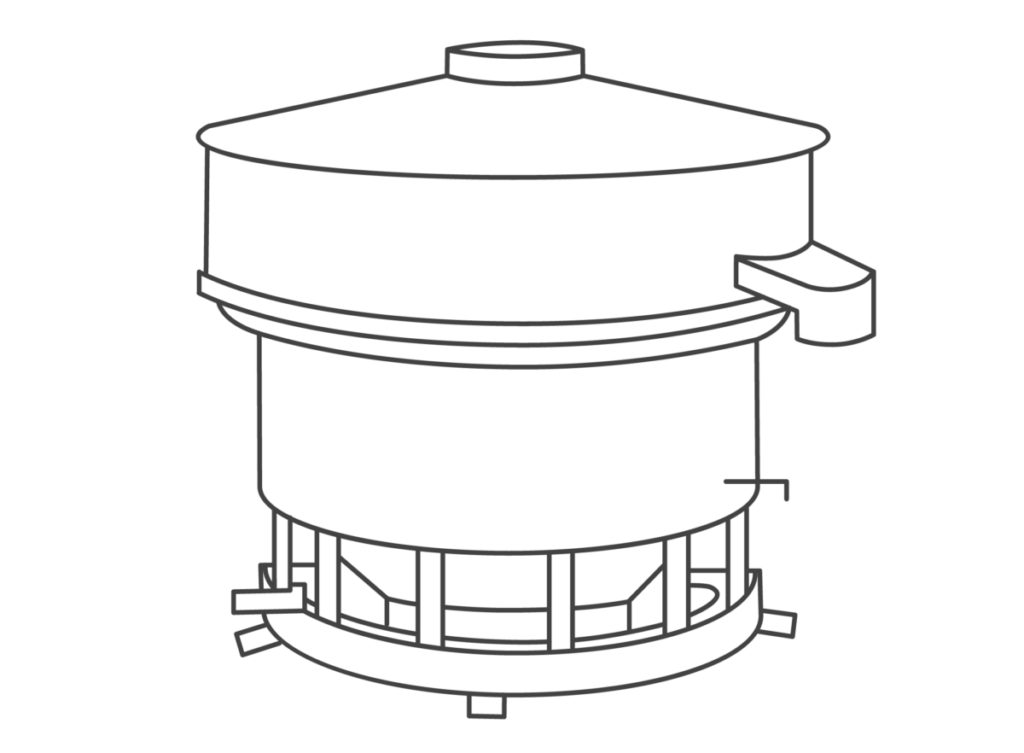

Vibrating Screen

Fine screens that vibrate at a high frequency to assist in dewatering fine solids, usually used with polymers or coagulant.

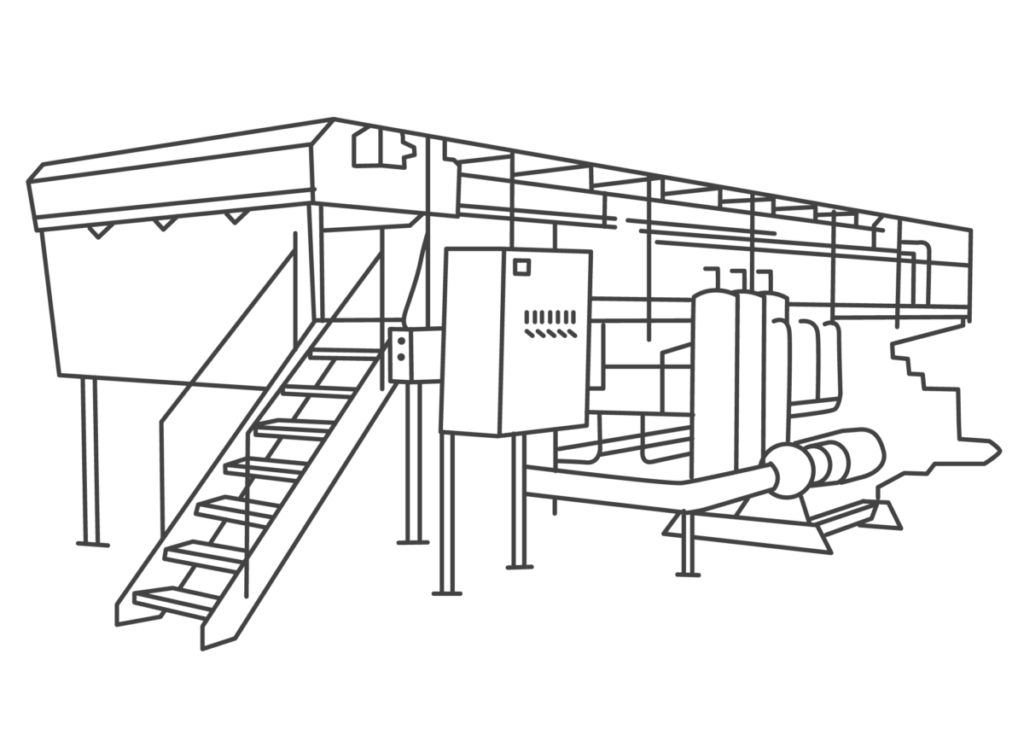

Dissolved Air Floatation(DAF)

Physical and chemical removal of fine solids by floating with very fine air bubbles assisted by polymers or coagulants.

Incline Screen

Similar to slope screens but with finer screens usually used with polymers or coagulants.

Dewatering

Belt Filter Press

A long screen in the form of a belt with rollers that allows for separation of fine solids usually used with polymers or coagulants also used for dewatering following other fine solids separation systems.

Plate Presses

Fine screens attached to a series of plates that are pressurized by the inflow of dilute waste usually used with polymers or coagulants. Also used for dewatering following other fine solids separation systems.

Centrifuge

Physical separation of fine particles by centrifugal force may or may not be assisted by polymers or coagulants, also used for dewatering following other fine solids separation systems.

Screw Press

A wedge-wire screen cylinder that manure is forced through by an auger to force out the water, back-pressure is maintained on the material in the cylinder by means of a gate or gates in the discharge of the cylinder.

Moving Disc Press

A cylinder made up of many vertically arranged plates that manure is forced through by an auger to force out the water; back-pressure is maintained on the material in the cylinder by means of a gate or gates in the discharge of the cylinder. This process may or may not be assisted by polymers or coagulants.

Vibratory Screen

Fine screens that vibrate at a high frequency to assist in dewatering fine solids, usually used with polymers or coagulant.

Driers

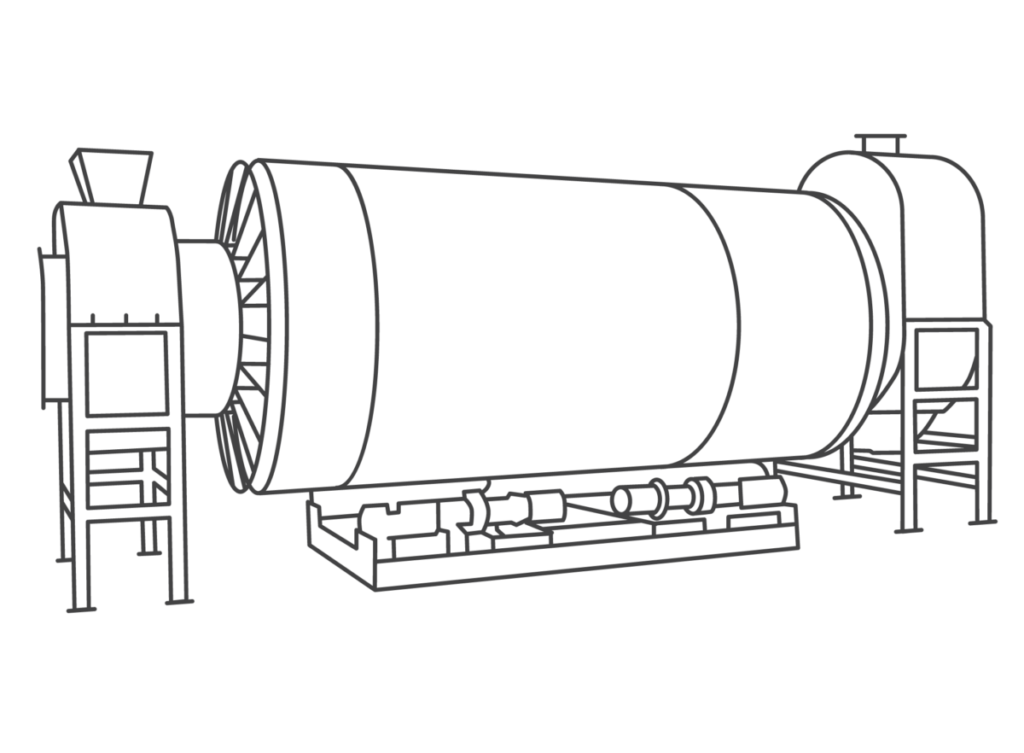

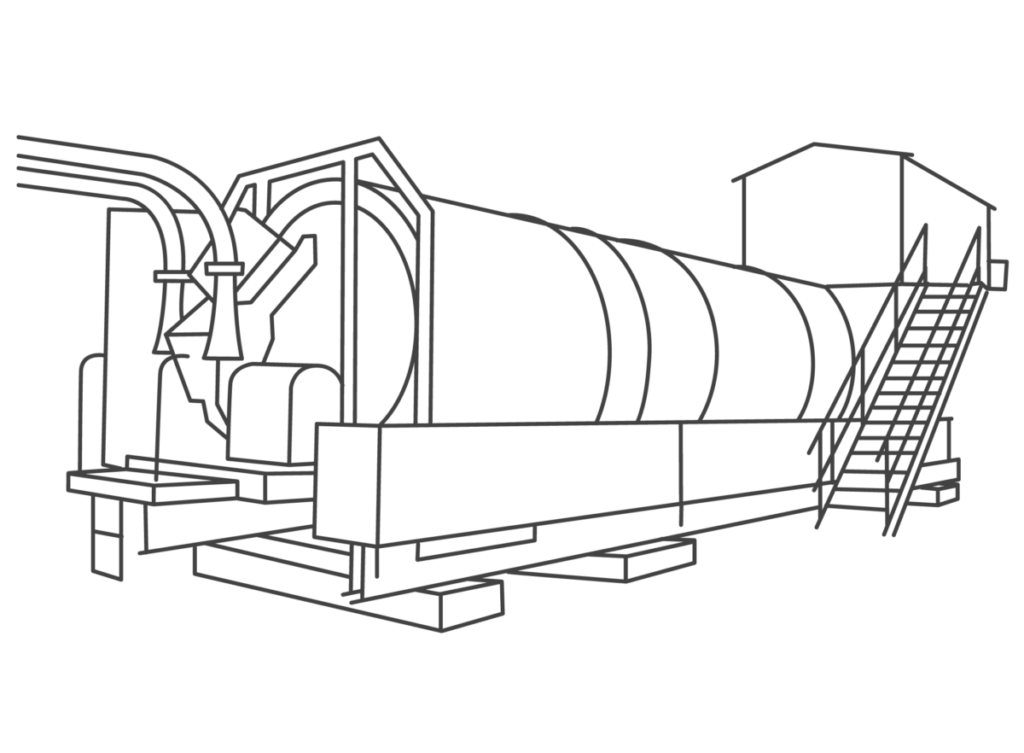

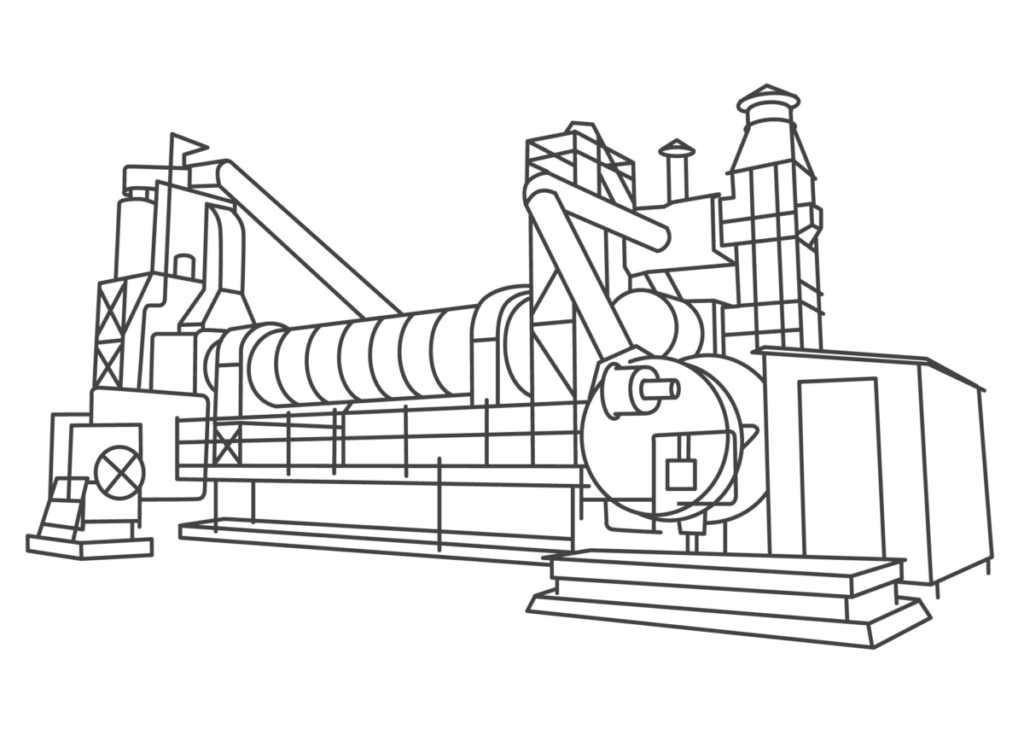

Drum Driers

A slightly inclined drum fed on high end with solids and counter-current flow of warm air starting on the lower end. With strategically placed lifters and rotation, effective air/solids mixing occurs for evaporation and drying of solids.

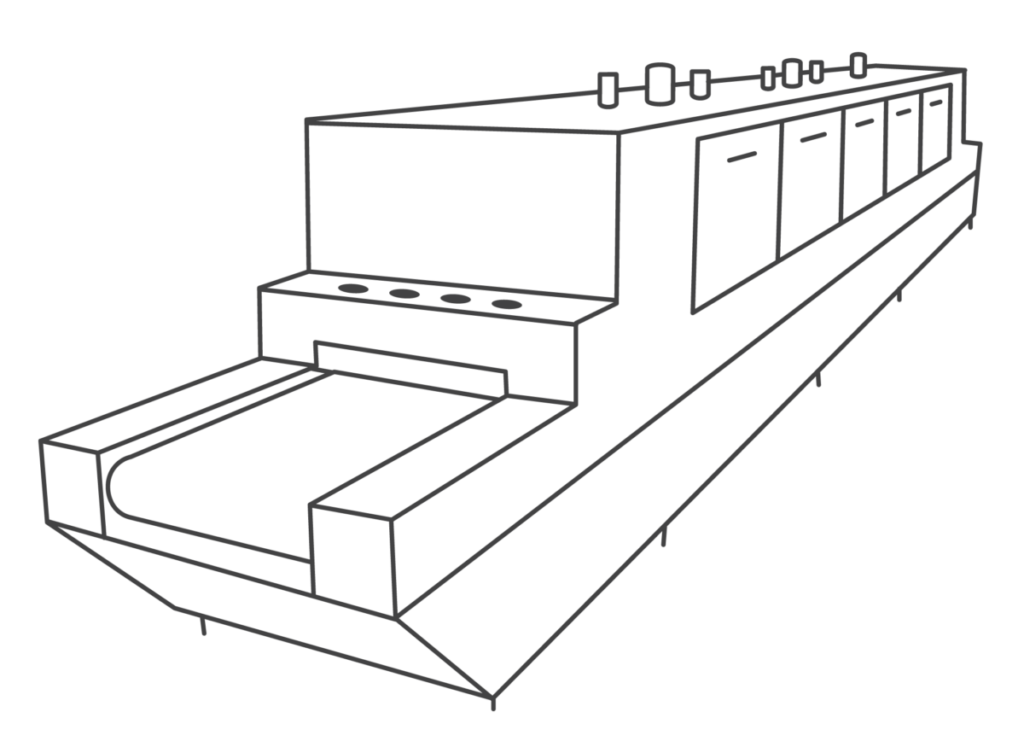

Belt Driers

A series of perforated steel plates which are chain driven to carry solids across a horizontal flow of warm air, inducing evaporation of moisture and drying of solids.

Bedding Recovery

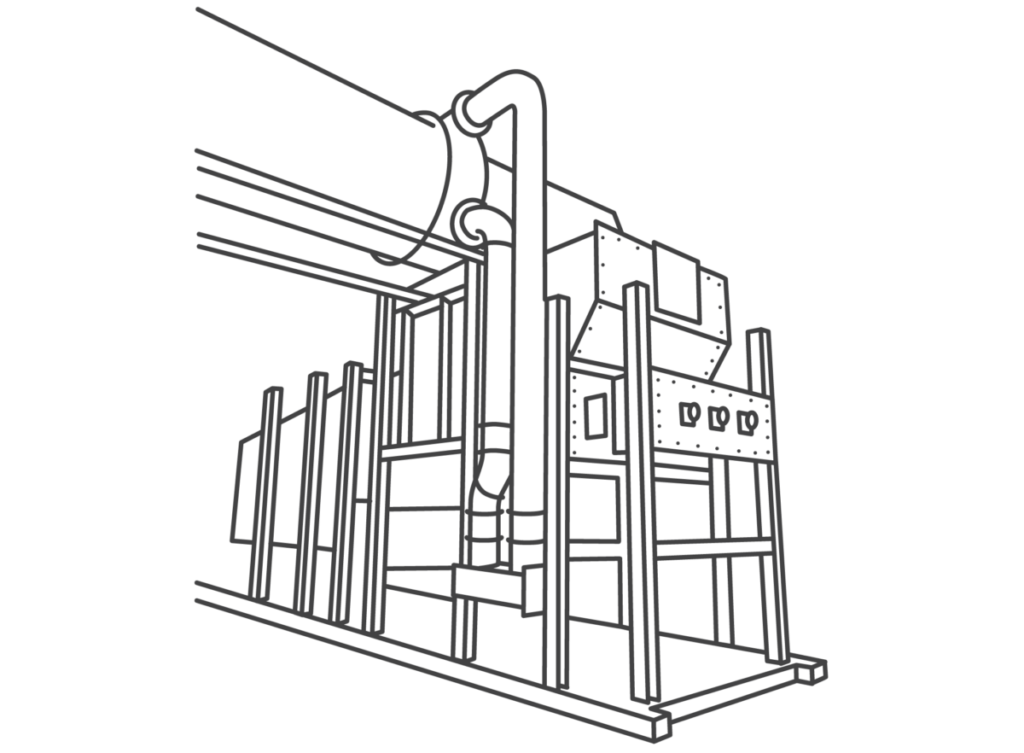

Composting Drums

Rotating drum with conveyed, separated manure solids rotating against hot air produced mechanically or by biological organisms, leading to an aerated, compost process during 1-3 day retention time.

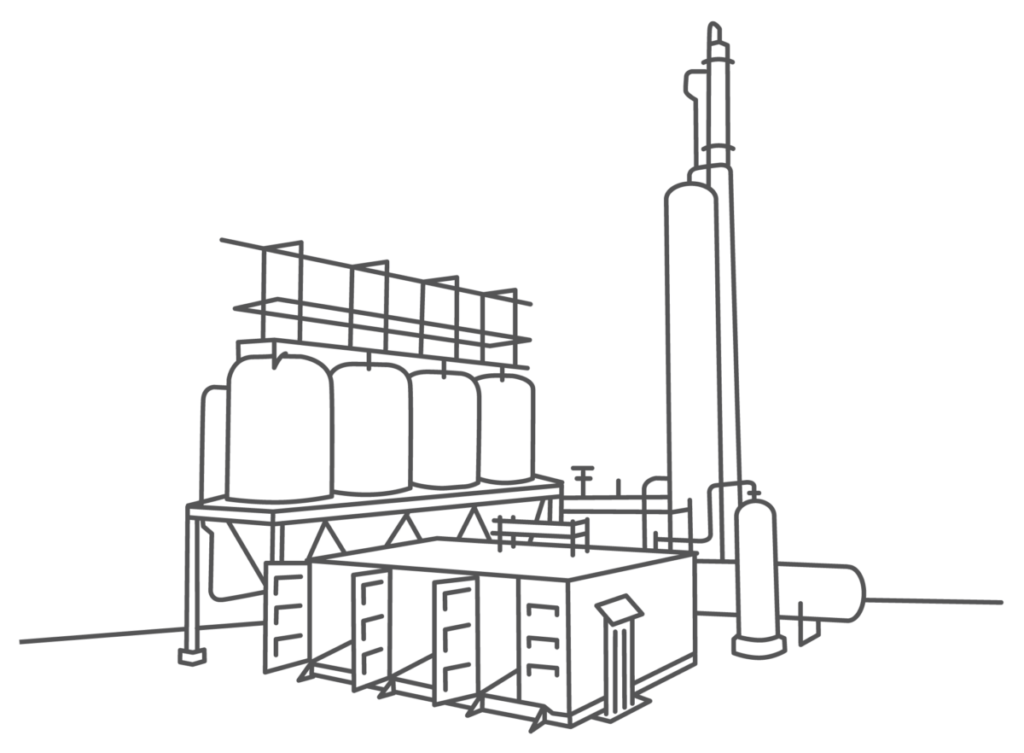

Energy Generation

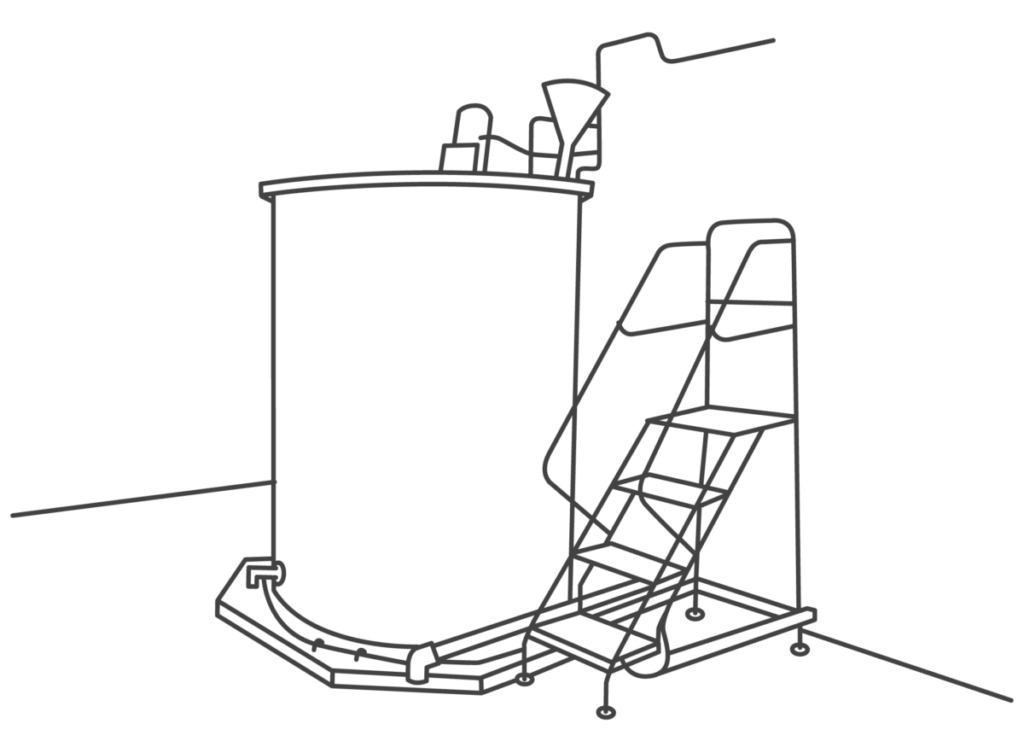

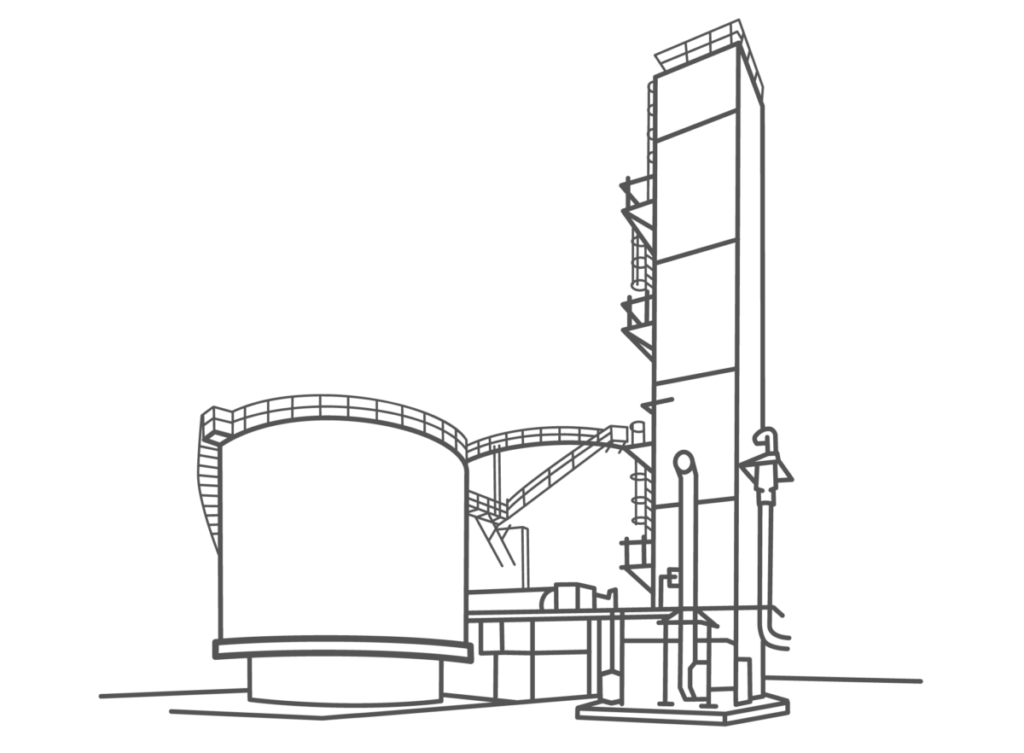

Anaerobic Digestion

The biological treatment of organic waste in the absence of oxygen, with assortment of microorganisms converting portions of organic carbon to biogas, composed primarily of carbon dioxide and methane. Methane is used as source of power, heat, and/or fuel.

Torrefaction

A lower temperature version of pyrolysis (approximately 200-370C) aimed at densifying the energy content of biomass solids, by producing primarily a bio-char or charcoal.

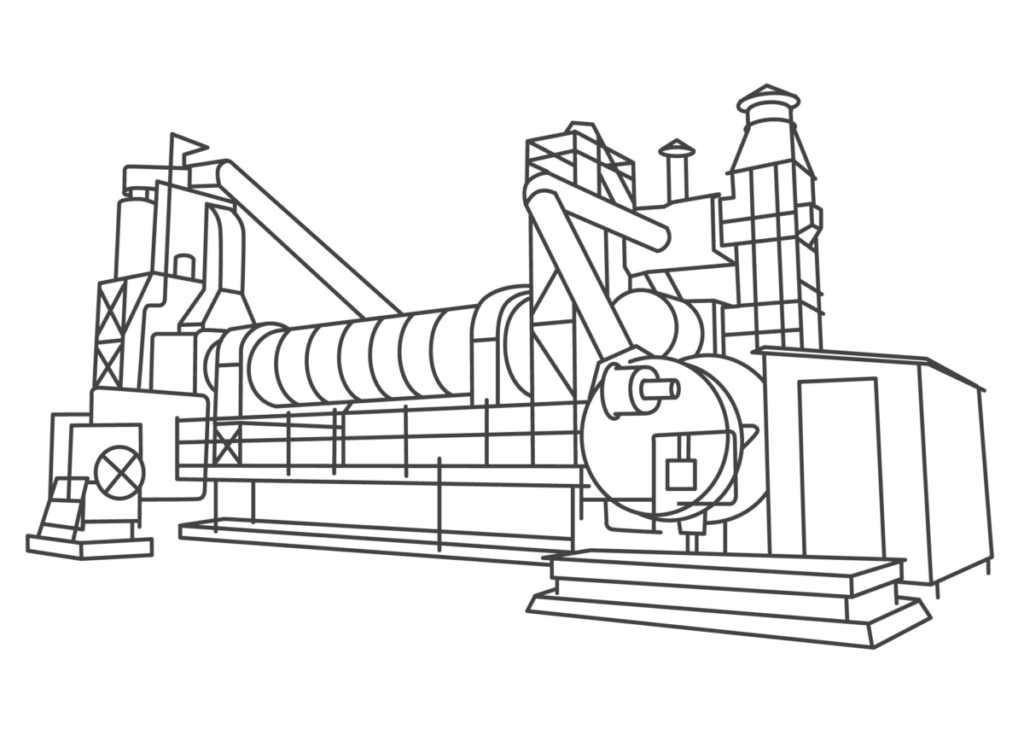

Pyrolysis

Use of moderate temperatures (approximately 400C or higher) in the absence of air to convert biomass solids into more energy-dense forms, producing combustible gases, liquids that can be further refined to liquid fuels and solid bio-chars.

Gasification

High temperature (>800C), thermochemical process in an oxygen starved environment that converts solid biomass to gases and ash or biochar. The gases can be used for heat, power, and fuel.

Gas Upgrading

PSA

Acronym for pressure swing absorption whereby high pressures and/or temperatures are used to selectively absorb biogas contaminants or specialized chemicals, allowing for the purification and release of methane. Absorbed material can have contaminants released with changes in pressure and temperature allowing for their repeated use.

Cryogenic Separation

Gas contaminants liquefy at varying cool temperatures as compared to methane; thus, these systems create a controlled environment where specific cool temperatures are achieved to maintain methane as a gas but other contaminants as a liquid, leading to subsequent purification.

Water Scrubbing

A physical process whereby varying water solubility of contaminants in biogas is used to separate out the methane, thus purifying. Key impurities like carbon dioxide and hydrogen sulfide are more soluble than methane, allowing for the separation. Post-separation, changes in temperature or pressure can release the impurities thus allowing for reuse of the water.

Biological H2S Removal

A group of aerobic microorganisms are cultivated in a controlled environment and fed contaminated biogas, feeding off the hydrogen sulfide in the process, and converting the sulfur to primarily solid elemental sulfur and thereby purifying the biogas.

Membrane Separation

Membranes can be designed to selectively attract contaminants while methane flows through the membrane. Membranes can be backwashed to remove contaminants for continued use.

Iron Sponge

A chemical process whereby iron salts or material dosed in iron salts is packed in a bed while contaminated biogas is blown across and through the bed. The hydrogen sulfide chemically reacts producing iron sulfide and purifying the biogas. Spent chemical containing iron sulfide can be land applied or landfilled.

Amine Scrubbing

A particularly absorbent chemical system involves the use of a chemical family called amines. This family of chemicals selectively absorbs both hydrogen sulfide and carbon dioxide while allowing for the flow through and purification of methane. The amine solution can be re-used after a cleaning step whereby changes in temperature or pressure release the hydrogen sulfide and carbon dioxide.

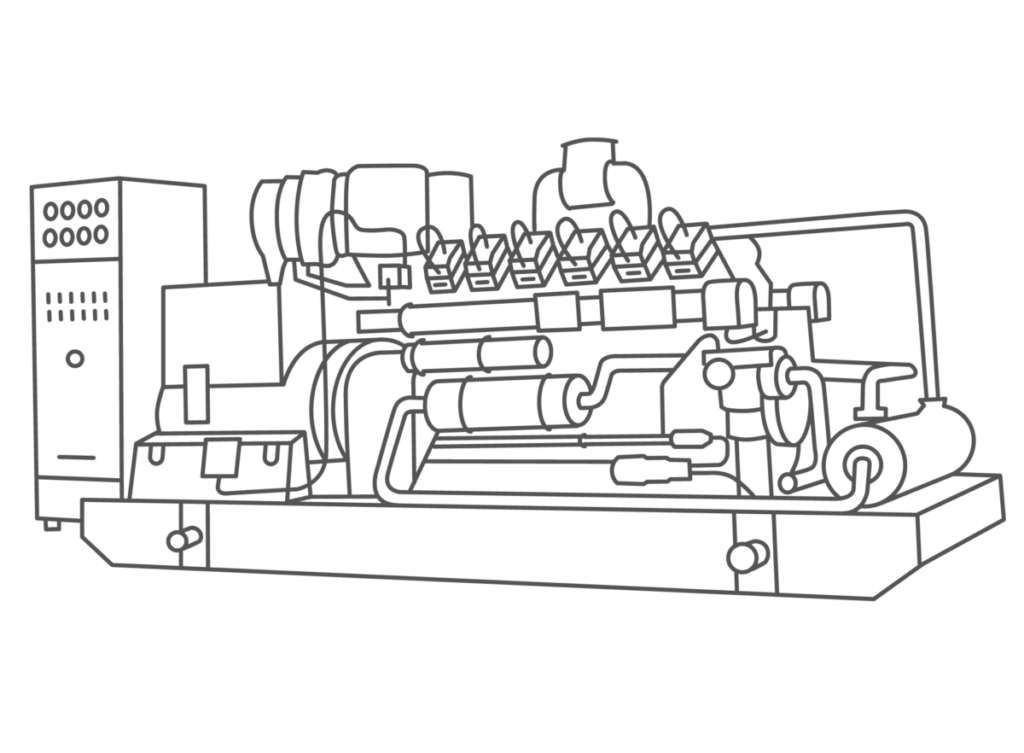

Electrical Production

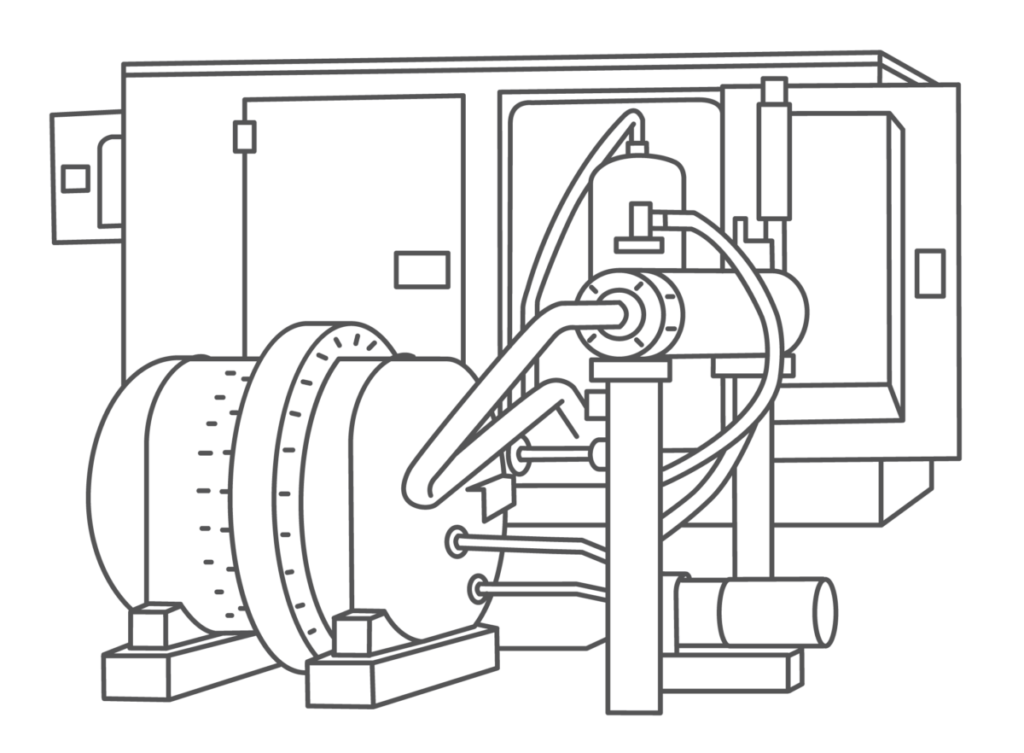

Internal Combustion Engine and Generator

Standard anaerobic digestion energy processing equipment whereby the raw or partially treated biogas is mixed with air and then combusted leading to mechanical energy in the form of moving pistons and rods. The mechanical movement of rods is then converted to electrical energy via use of a companion generator utilizing the principles of electron movement in wires when rods move in an encircling magnet.

Fuel Cell

Unlike a chemical battery which contains chemical fuel that allows for a cathode/anode redox reaction to convert chemical energy to moving electrons and power, a fuel cell continually supplies a fuel, in this case, biogas, to the system, thus continually producing power for as long as the fuel is supplied.

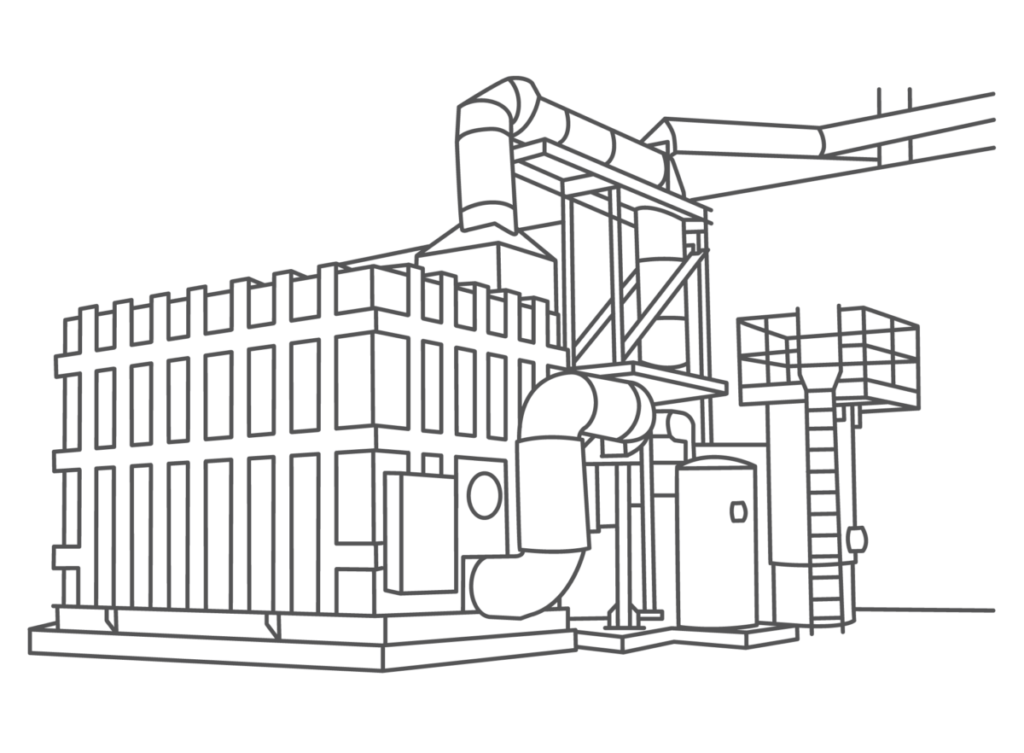

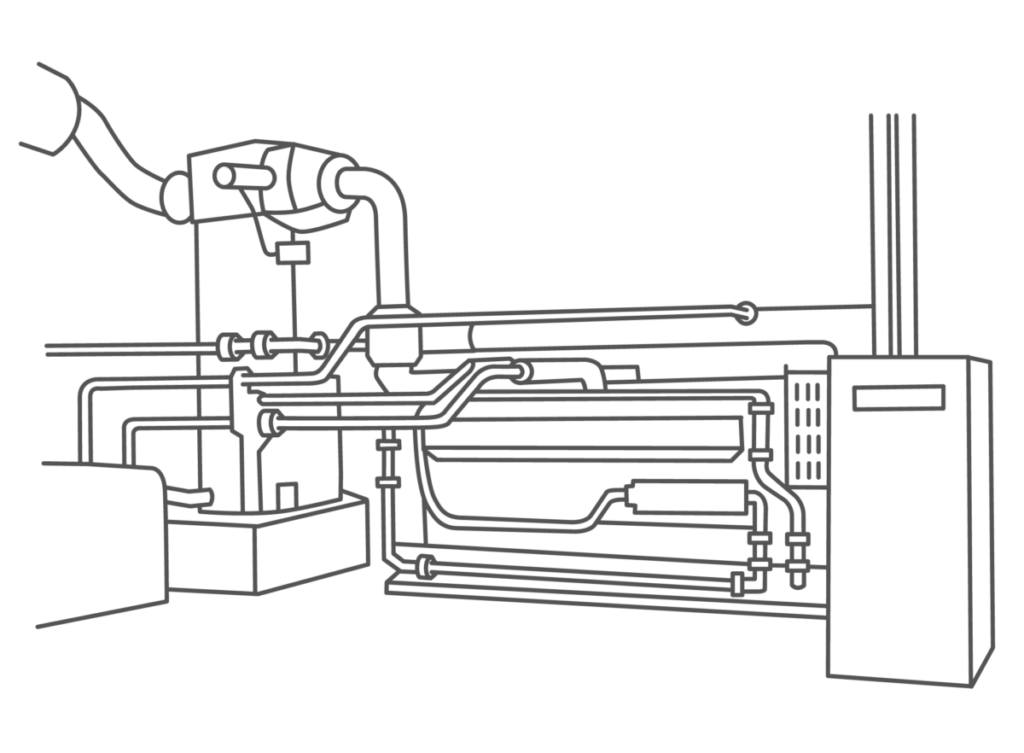

Combined Heat and Power

In the internal combustion engine/generator system, considerable chemical energy in the biogas is lost to heat during the combustion process. Heat recovery units can be attached to the system recovering a significant portion of the energy to a hot water system. The combined system is referred to as CHP or combined heat and power system.

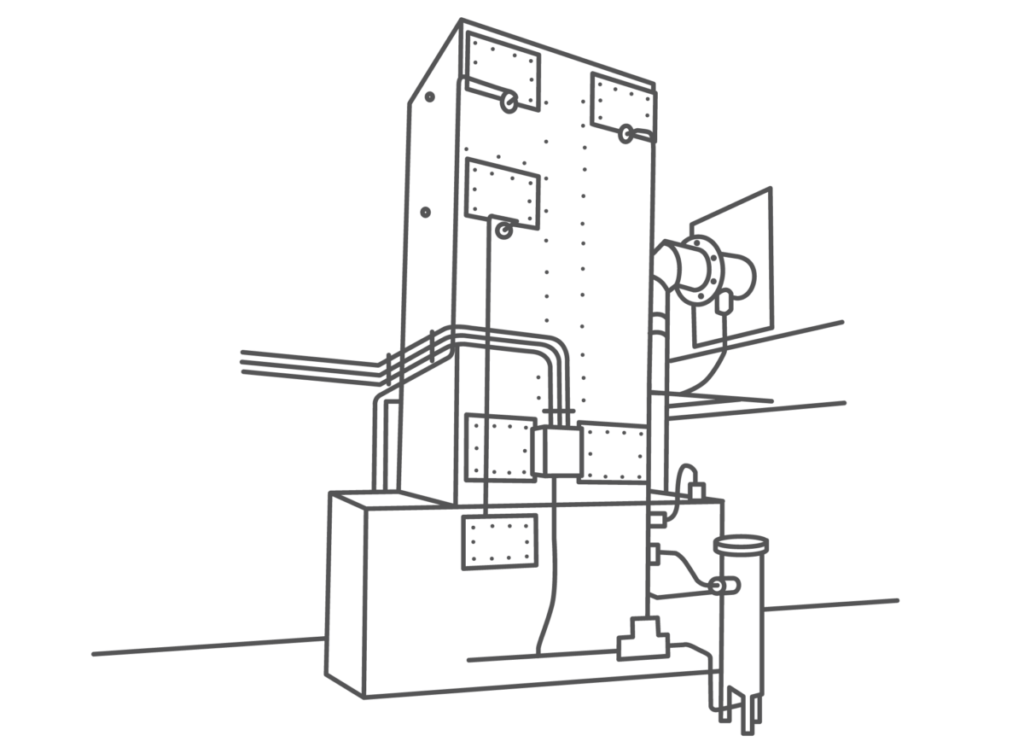

Steam Generator

An external combustion system whereby the biogas is first combusted to produce hot gases which in turn allow for the heating of water above the boiling point to produce steam. The steam can then be used to induce mechanical work and ultimately electrical power.

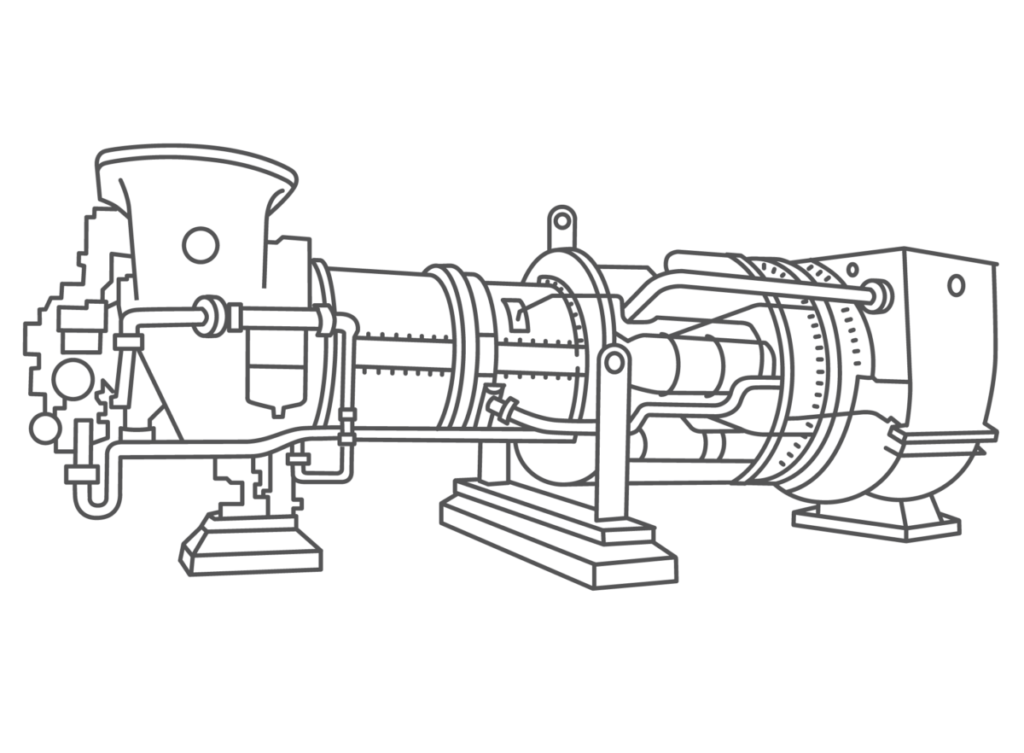

Gas Turbine and Generator

A version of the internal combustion system whereby oxygen/air is first pressurized and then mixed with biogas to induce combustion. The resulting high pressure, high temperature exhaust is sent to a turbine which reduces the pressure while creating mechanical work in the form of a moving rod or in a final form, electrical power.

Sterling Engine and Generator

A heat engine whereby hot gases are cyclically compressed and expanded at varying temperatures via connection with a regenerator. The net result is a conversion of some thermal energy to mechanical work which in turn can lead to electrical power.

Other Nutrient Recovery

Ammonia Stripping

Various approaches, including air, steam, carbon dioxide, membrane, etc. that use temperature, pressure, and chemicals to preferentially adjust the pH and therefore the form of the ammonia from soluble ionic ammonia to free, gaseous ammonia. The gaseous ammonia is then collected and often converted to a more stable ammonia-salt form using various acids, i.e., sulfuric acid to ammonium sulfate fertilizer.

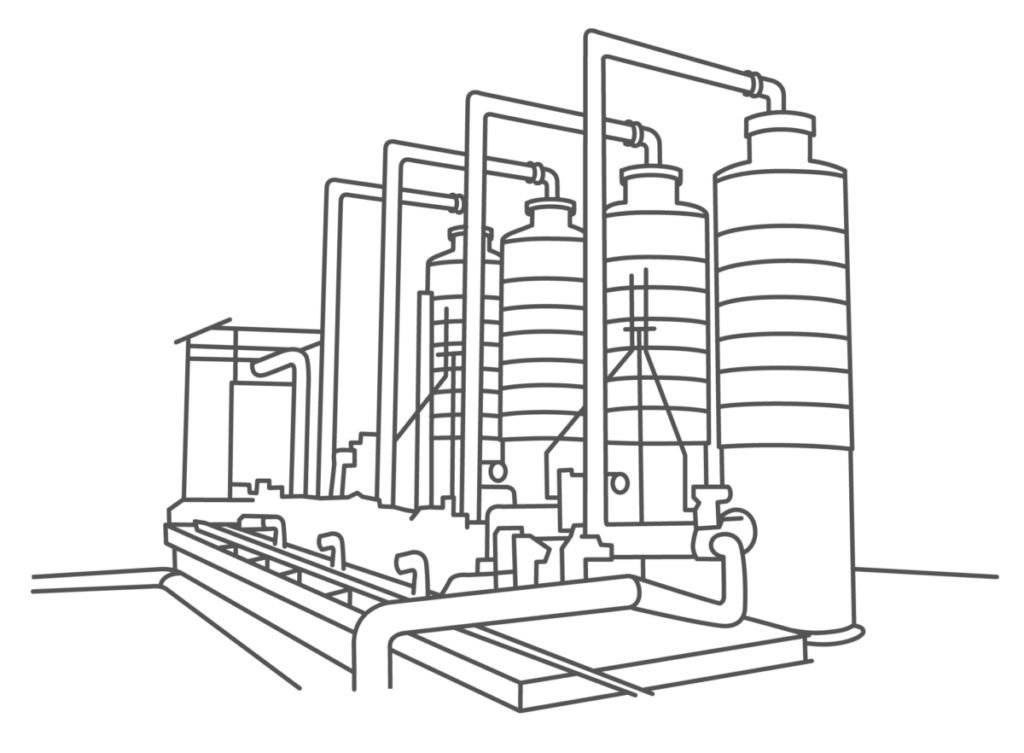

Evaporative Systems

Beyond manure drying, which is related to manure solids, manure wastewater can be partially or completely dried by evaporating the liquid through a series of cascading evaporative reactors. Energy inputs and balances can be a concern while treatment of volatiles in the evaporated liquid is also required.

Nitrification/Denitrification

Both traditional and modified methods to convert ammonia nitrogen biologically to non-reactive nitrogen gas that can be released to the atmosphere. Various organisms and degrees of aerobic and anaerobic contact allow for the conversion.

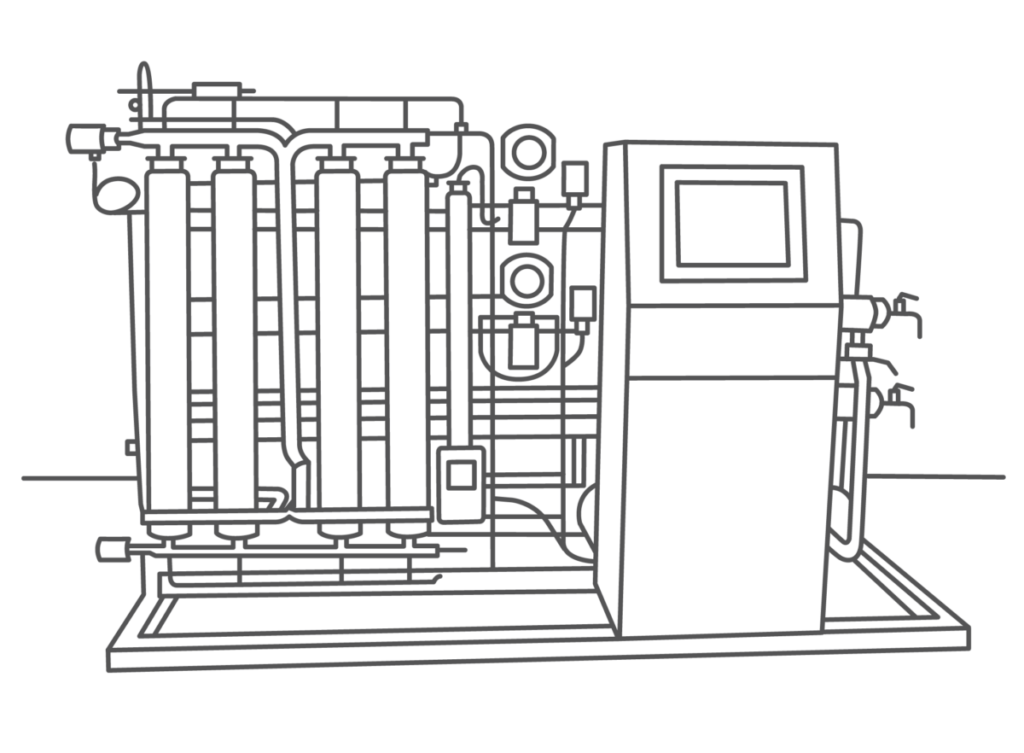

Membrane Systems

A series of membranes, either micro-filtration, ultra-filtration and/or reverse osmosis filtration can be used singly or in a combination to remove various sized contaminants within the wastewater, using high pressure flow through a membrane designed to selectively remove certain particle sizes. Membranes can be used in concert with digesters, or ammonia removal systems to significantly remove solids, nutrients, and pathogens. Incorporation of reverse osmosis can remove dissolved salts producing clean water. Use produces a reject stream composed of material not passing the membrane, thus cannot be considered zero discharge.

Vermifiltration

Higher organisms such as red worms within a media filter-bed (i.e., a bed of wood chips) can convert ammonia nitrogen to bound organic nitrogen in the worms/castings, non-reactive nitrogen gas as well as other forms, thus vastly reducing the ammonia content of the wastewater while making saleable worm/casting by-products.

Struvite Crystallization

A process whereby existing soluble forms of phosphorus in the wastewater are induced to crystallize as a struvite crystal which is a combination of ammonia, magnesium, and phosphorus, producing a dry, high phosphorus content, slow-release, pelletized fertilizer.